In the world of art and engineering, the process of A356 Aluminum Casting stands out as a true testament to human creativity and innovation. This intricate technique has been used for centuries to create a wide range of products, from sculptures and automotive parts to aerospace components. The beauty of aluminum casting lies not only in its versatility but also in the meticulous craftsmanship required to sculpt intricate and durable pieces from this lightweight metal.

The Artistry of Aluminum Casting

A Timeless Craft

Aluminum casting, also known as aluminum alloy casting, has a rich history dating back thousands of years. Ancient civilizations, including the Egyptians and Chinese, were among the first to experiment with the casting process. They utilized sand casting and lost-wax casting techniques to create exquisite artworks and religious artifacts.

Today, aluminum casting has evolved into a sophisticated and highly specialized craft. Skilled artisans and engineers work hand in hand to produce everything from delicate sculptures to intricate automotive engine components. The enduring appeal of this process lies in its ability to transform molten aluminum into stunning and enduring forms.

Unparalleled Versatility

One of the most remarkable aspects of aluminum casting is its incredible versatility. Aluminum alloys can be tailored to suit various applications, making it a top choice for many industries. Whether it’s the automotive, aerospace, or art world, aluminum casting provides the freedom to create products that are both functional and aesthetically pleasing.

In the realm of art, sculptors have harnessed the flexibility of aluminum casting to bring their visions to life. The metal’s malleability allows artists to experiment with intricate designs and produce sculptures that seem almost weightless. Moreover, aluminum’s corrosion resistance ensures that these sculptures can withstand the test of time, making them ideal for both indoor and outdoor installations.

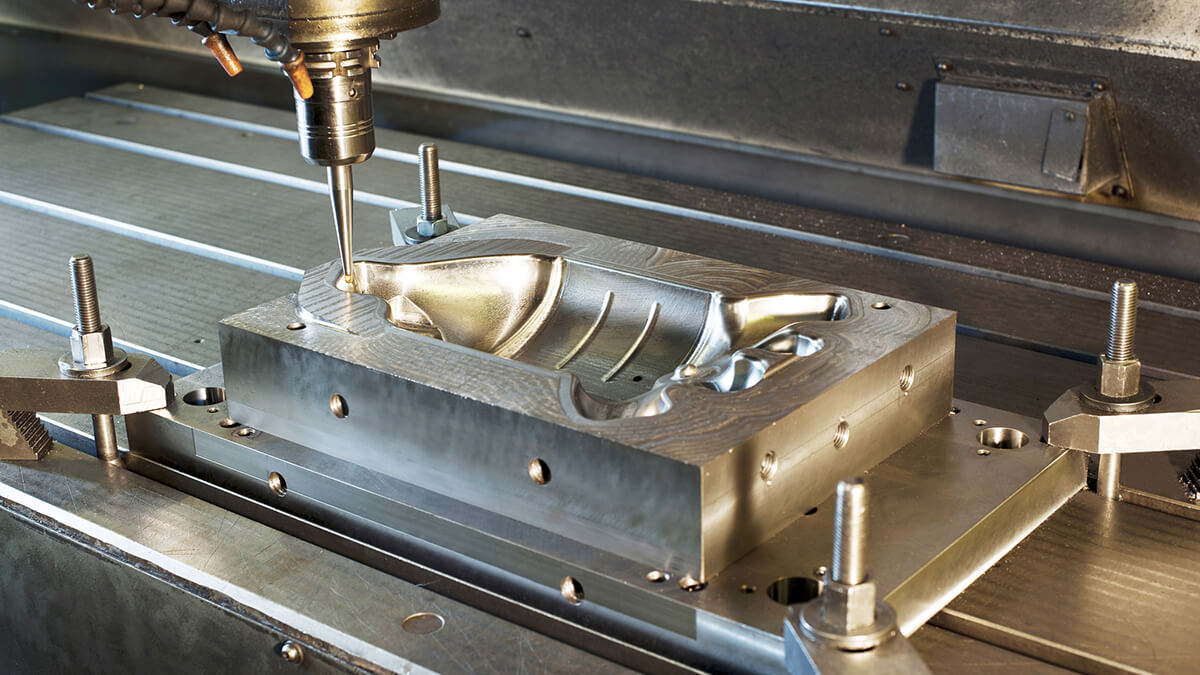

Precision and Complexity

The process of aluminum casting demands precision and attention to detail. It begins with the creation of a mold, typically made of sand or plaster, into which molten aluminum is poured. Once the aluminum cools and solidifies, the mold is removed to reveal the final piece. The intricacy of this process allows for the production of highly detailed and complex sculptures.

Sculptors often choose aluminum casting because it offers a level of intricacy that few other materials can match. The metal can capture the fine details of facial expressions, the delicate curves of a figure, or the intricacies of a botanical subject. This level of precision enables artists to create lifelike sculptures that evoke emotion and captivate viewers.

The Engineering Marvels of Aluminum Casting

Lightweight and Durable

Beyond the world of art, aluminum casting has earned its place in the field of engineering. Its unique combination of lightweight properties and durability makes it an ideal material for aerospace and automotive applications.

In the aerospace industry, where every ounce matters, aluminum casting plays a vital role. Aircraft components like engine housings, landing gear, and structural elements are often cast from aluminum alloys. This not only reduces the overall weight of the aircraft but also ensures that it can withstand the rigors of flight.

Similarly, in the automotive sector, aluminum casting has become a cornerstone of modern vehicle design. Engine blocks, transmission cases, and suspension components are commonly cast from aluminum alloys. These parts are not only lighter than their steel counterparts but also exhibit impressive strength and corrosion resistance.

Sustainable Innovation

In today’s environmentally conscious world, aluminum casting also aligns with sustainable practices. Aluminum is highly recyclable, and the casting process itself generates minimal waste. This focus on sustainability has made aluminum casting a preferred choice for industries looking to reduce their carbon footprint.

Conclusion

The beauty of aluminum casting lies in its ability to seamlessly blend art and engineering. Whether creating stunning sculptures that grace galleries and public spaces or engineering components that propel us into the future, aluminum casting is a testament to human ingenuity and creativity.

From its ancient origins to its cutting-edge applications in the modern world, aluminum casting continues to evolve and inspire. Its versatility, precision, and sustainability make it a true marvel of human innovation—one that promises to sculpt excellence for generations to come.